of worldwide CO2 emissions are accounted for by industry, according to the International Energy Agency.

RONLOG Logistics Center – CO₂-neutral since 2021

The RONLOG logistics center achieved climate neutrality in Scope 1 and 2 in 2021. RONAL GROUP is thereby making an important contribution to the Paris Agreement on climate protection.

GREATER EFFICIENCY MEANS MORE SUSTAINABILITY

The Paris Agreement on climate change, ratified in 2015, aims to limit man-made global warming to below two degrees Celsius compared to pre-industrial levels. Industrial companies like RONAL GROUP can have a major influence on this. According to the International Energy Agency (IEA), industry accounts for around 32% of global carbon dioxide emissions. That is why the RONLOG logistics center in Forst, Germany, has been working for years to reduce its own energy consumption. With a series of efficiency measures, RONLOG has succeeded in reducing its own gas and electricity consumption and thus reducing greenhouse gas emissions in the Scope 1 and 2 categories (Explanations Scope 1-3).

EVERY CONTRIBUTION COUNTS

To reduce energy consumption, RONLOG has, among other things, introduced heat recovery systems for two compressors and equipped the packaging plant with a standby circuit to switch off pneumatic components. The logistics center’s vehicle fleet now consists of hybrid vehicles, and two charging stations for electric cars at the Forst site promote sustainable mobility. Work bicycles for employees also enable them to make their own contribution to reducing CO2.

RIGHT AT THE SOURCE

Since 2017, RONLOG has been sourcing 100% of the electricity it needs from renewable sources with a certificate of origin. This means that greenhouse gas emissions from Scope 2 have been avoided completely. Of course, it shouldn't stop there. The company is looking into the possibility of installing its own photovoltaic system to generate part of the electricity itself and to further reduce electricity consumption through intelligent lighting technology. Since 2021, RONLOG has also been purchasing CO2-neutral gas directly from a utility company. The supplier confirms this in the form of certificates and TÜV Nord provides the external validation.

MORE LOADING SPACE ON TRUCKS

RONLOG compensates unavoidable emissions of around 60 metric tons of CO2 annually (mainly from refrigerants and fuels) with Gold Standard certificates. However, further measures will aim to reduce this in the future. In cooperation with an external freight forwarder, RONLOG is looking into the possibility of transporting wheels to customers in the future using long trucks that provide more loading space and volume. The goal for the coming financial years is to reduce emissions from Scope 3 and to compensate unavoidable emissions by 2030.

MEASURES IMPLEMENTED BY EFFICIENCY FOR REDUCING CO₂ AT RONLOG

- Heat recovery systems for two compressors

- Switching to green electricity

- Converting to compensated gas

- The installation of a standby circuit to switch off pneumatic components on the packaging line

- Feeding scrap wheels to other sites for remelting

- Carrying out leakage tests to detect pressure losses

- Converting the site fleet to hybrid vehicles

- Installing and commissioning two e-charging columns

- Introducing work bikes for employees

- Purchasing company bike for in-house mail at the Forst site

- Self-generating demineralized water to fill batteries

- Paperless and digital picking

- Use of paper labels

- Use of paper based adhesive tape

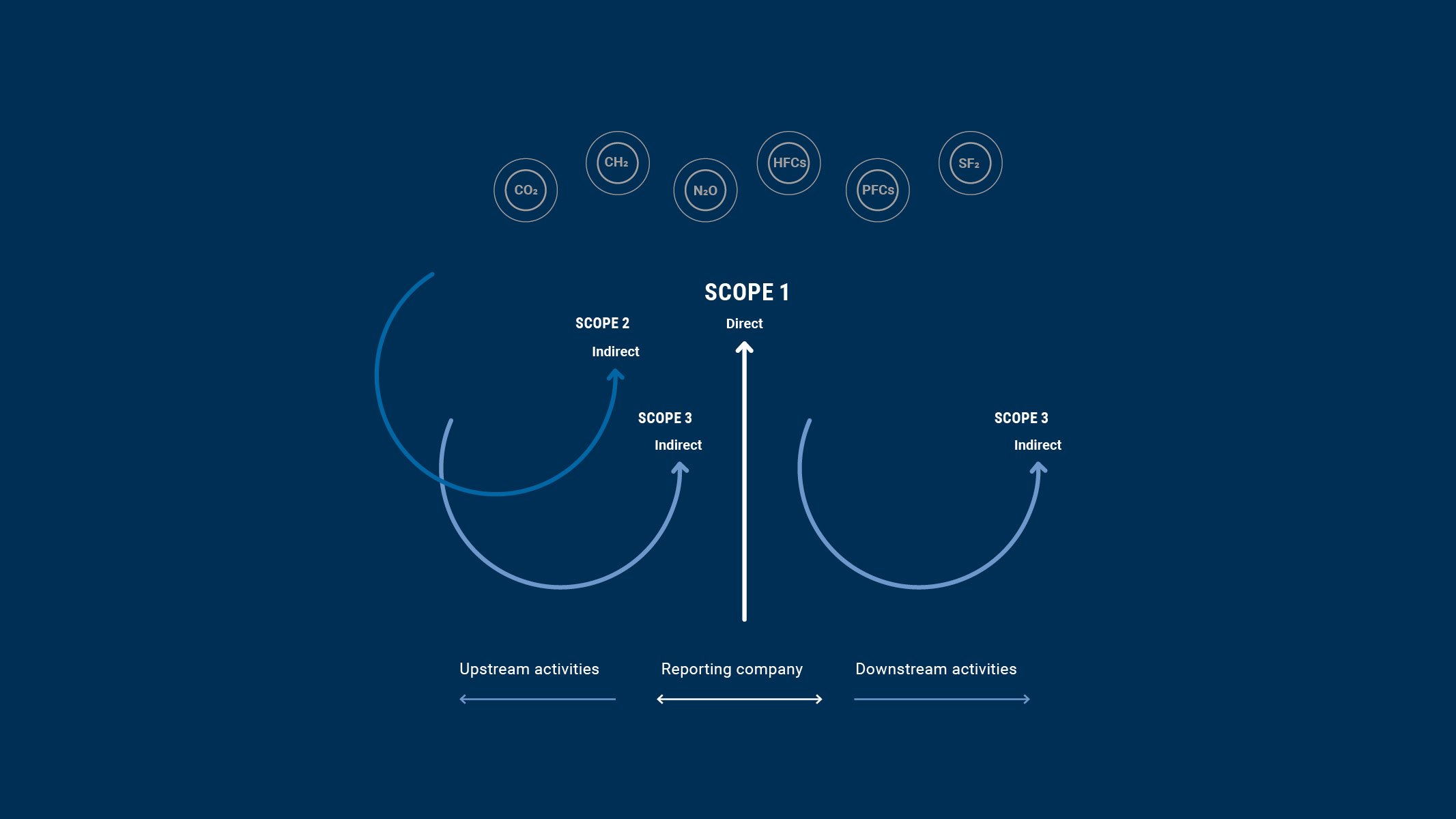

EMISSIONS THROUGHOUT THE ENTIRE VALUE CHAIN BASED ON THE GREENHOUSE GAS (GHG) PROTOCOL

SCOPE 1

Scope 1 includes all direct emissions resulting from production, e.g. from fuel combustion, coolants or emissions from the company's own vehicle fleet. These are emissions from sources directly controlled by companies.

SCOPE 2

Scope 2 includes all indirect emissions caused by the energy used. In other words, emissions from purchased energy consumed by the company, such as electricity, steam, district heating or district cooling.

SCOPE 3

All other emissions are combined in Scope 3. These occur upstream and downstream in the supply chain, for example through the use of resources or products and services, office materials, events, employee commuter miles, and waste disposal.